The Ultimate Guide To Dehydrated Fruits & Vegetables and their Labelling

January 25, 2023

Dehydration of fruit and vegetables is one of the oldest varieties of food preservation techniques well-known to man and consists primarily of establishments engaged in sun drying or by artificial means dehydrating fruits and vegetables. Though food preservation is the primary reason for dehydration, dehydrated fruits and vegetables additionally lower the price of packaging, storing, and transportation by reducing the burden and volume of the ultimate product.

What are dehydrated fruits and Vegetables?

According to FSSAI

Dehydrated Vegetables (4.2.2.2) and fruits (4.1.2.2) are the products, prepared from edible portions of a suitable variety of sound fruits or vegetables, free from insect or fungal infection, free from blemishes, suitably prepared, from which moisture has been removed under controlled conditions of temperature, humidity & airflow, to the extent that the product is preserved.

It may be whole, sliced, quarters, pieces, flakes, kibbled granules or powdered. The finished product should have uniform color and should be free from discoloration due to scorching or enzymatic reaction. It shall be free from stalks, peels, stems and extraneous matter. When in powder form, it shall be free-flowing and free from agglomerates.

Dehydration of fruits and vegetables keeps their original nutritional value intact. As a lightweight, nutrient-dense option, dehydrated fruits and vegetables are a go-to for hikers and travelers looking to save space.

Given the improvements in the quality of dehydrated foods, together with the multiplied specialize in instant and convenience foods; the potential of dehydrated fruits and vegetables is larger than ever.

Drying or dehydration is the elimination of the bulk of water contained within the fruit or vegetable and the primary stage within the production of dehydrated fruits and vegetables.

Significance of Dehydration of fruits and vegetables

Dehydrated foods are tasty, nutritious and lightweight.

Dehydrated fruits and vegetables are available in the market throughout the year.

Dehydrated food products are easy to use.

Due to their purified finished form dehydrated food products does not contain any wastage.

The energy input is less than what is needed to freeze or can, and the storage space is less than that needed for canning jars and freezer containers.

Dehydrated fruits and vegetables help in stabilizing the prices of seasonal produce.

Dehydrated Food Products

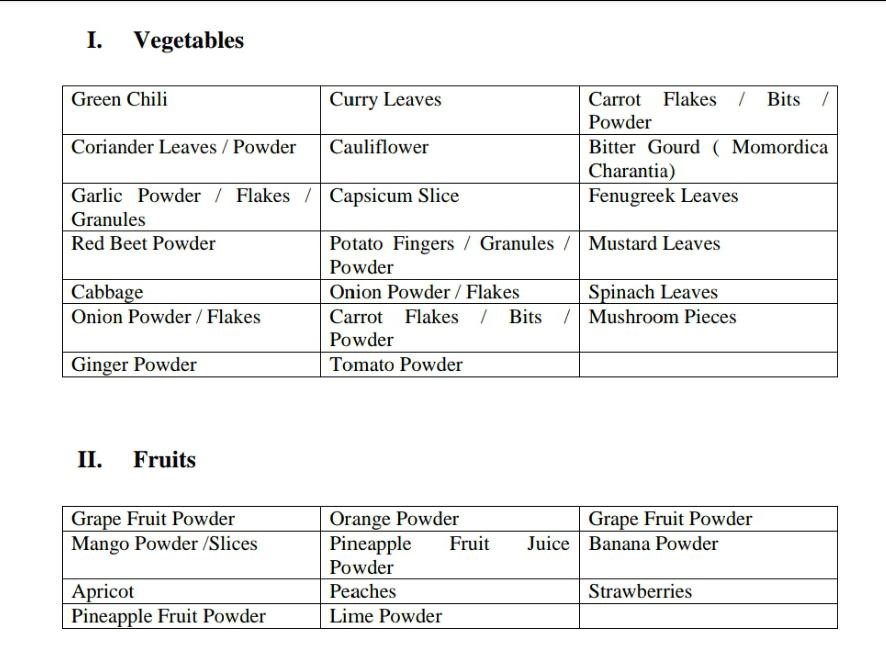

Although dehydration is an energy-intensive process yet fruits and vegetables can be converted into value-added products by using solar energy options and exploiting the remote area labor force. Dehydrated food products have a potential market nationally and internationally. There is a wide range of agricultural products which can be dehydrated and marketed locally or internationally. Following are the common dehydrated fruits and vegetables which are consumed in today’s world.

Nutritional value of dehydrated fruits and vegetables.

The dehydrating process retains a food’s original nutritional value. For example, apple chips will have the same calorie, protein, fat, carbohydrate, fiber, and sugar content as fresh fruit.

However, because dehydrated food product loses their water content, it’s usually smaller in size and has more calories by weight.

Dehydration also maintains the nutritional value of dehydrated fruits and vegetables for much longer than their fresh counterparts. Research shows that fresh produce loses its vitamin, mineral, and antioxidant content within a few days of refrigeration — with reductions as high as 50% for some nutrients.

Make your nutrition label for dehydrated fruits and vegetables online in just a few minutes using FoLSol India’s first digital food labeling solution.

How are fruits and vegetables dehydrated?

Dried or dehydrated fruits and vegetables can be produced by a variety of processes. In general, dried or dehydrated fruits and vegetables undergo the following process steps: pre-drying treatments, such as size selection, peeling, and color preservation; drying or dehydration, using natural or artificial methods; and post-dehydration treatments, such as sweating, inspection, and packaging.

Pre-drying Treatments - Pre-drying treatments prepare the raw product for drying or dehydration and include raw product preparation and color preservation. Raw product preparation includes selection and sorting, washing, peeling (some fruits and vegetables), cutting into the appropriate form, and blanching (for some fruits and most vegetables). Some fruits and vegetables are blanched by immersion in hot water or exposure to steam. The final step in the pre-dehydration treatment is color preservation, also known as sulfuring. The majority of fruits are treated with sulfur dioxide (SO ) for their antioxidant and preservative effects.

Dehydration - Drying or dehydration is the removal of the majority of water contained in the fruit or vegetable. Several drying methods are commercially available and the selection of the optimal method is determined by quality requirements, raw material characteristics, and economic factors. There are three types of drying processes: sun and solar drying; atmospheric dehydration including stationary or batch processes, continuous processes, and sub-atmospheric.

Post-dehydration Treatments - Treatments of the dehydrated product vary according to the type of fruit or vegetable and the intended use of the product. These treatments may include sweating, screening, inspection, instantization treatments, and packaging. Sweating involves holding the dehydrated product in bins or boxes to equalize the moisture content. Screening removes dehydrated pieces of unwanted size, usually called "fines". The dried product is inspected to remove foreign materials, discolored pieces, or other imperfections such as skin, carpel, or stem particles. Instantization treatments are used to improve the rehydration rate of the low-moisture product.

Packaging is common to most all dehydrated products and has a great deal of influence on the shelf life of the dried product. Packaging must protect the product against moisture, light, air, dust, microflora, foreign odor, insects, and rodents; provide strength and stability to maintain the original product size, shape, and appearance throughout storage, handling, and marketing; and consist of materials that are approved for contact with food.

According to the Food safety and standards (packaging and labeling) regulations, candied fruits and peels and dried fruits and vegetables can be packed in paper bags, cardboard or wooden boxes, new tins, bottles, jars, aluminium and other suitable approved containers.

Food labeling for dehydrated fruits and vegetable

Labeling requirements for dehydrated fruits and vegetables should comply with Food Safety and Standards (Packaging and labelling) Regulations, 2011. Packaged Food product Establishments face many challenges in the nutrition labelling of their food products like analyzing nutrition value via laboratory methods or calculating manually, being regulatory complaint, fear of portraying negative nutrition information as well as additional cost and planning.

To negate the challenges listed above there is a need for a digital platform. FoLSol® is India’s 1st digital food labelling solution that takes care of packaged food labelling. It is a platform that will also highlight the positives of your food product through health tags such as protein-rich, source of fibre, etc. The service is not only cost-effective but also very easy to use. Benefits include listing of ingredients, comprehensive nutrition information, health claims, allergens, serving size, ingredient modification feature, easy downloads and printouts and much more all of which is FSSAI complaint. To know more about FoLSol, visit https://www.foodlabelsolutions.com

About LabelBlind®

Established in 2018 and based in Mumbai, LabelBlind® specialises in the area of Digitising Food Labelling and Regulatory Compliance. FoLSol® by LabelBlind® presents India’s 1st Digital Food Labelling Solution. The SaaS platform supports Food Businesses to be Labelling Compliant and Build Consumer Trust. FoLSol® by LabelBlind® is designed to strengthen the food labelling ecosystem across a wide spectrum of services including, Packed Food Labelling, Menu Labelling, Exports Labelling, Nutraceuticals and Food Supplements Labelling and Labelling for Ecommerce players. FoLSol® Digital Food Labelling Solution is fast, accurate, and cost effective. The company is ISO9001 certified in its processes.

Zahra Merchant (M.Sc. Food Processing & Preservation)

Zahra is very communicative, detail oriented and a team player. She is very proud of having the ability to multitask and manage time efficiently.